Understanding the importance of hulling and drying highlights why these stages are essential for producing high-quality pistachios.

What is Hulling?

Hulling is the process of removing the outer shell, or hull, of freshly harvested pistachios. This outer layer is soft and moist, making it susceptible to mold and microbial growth if not removed promptly. The hulling process typically begins within 24 hours of harvesting to preserve the nut’s integrity and prevent spoilage.

Modern hulling facilities use mechanical hullers that separate the soft hull from the hard shell while minimizing damage to the kernel inside. The process is carefully monitored, as excessive pressure or speed can crack the shell or bruise the nut, reducing its market value. Proper hulling also prepares pistachios for subsequent drying and sorting, ensuring uniformity and quality.

Why Drying is Crucial

After hulling, pistachios contain residual moisture that must be reduced to safe levels for storage and transport. Drying is essential to prevent mold, maintain flavor, and extend shelf life. Improper drying can result in nuts that are prone to spoilage, shrinkage, or off-flavors, which are detrimental to both domestic sales and international exports.

There are several drying methods, including sun drying and mechanical drying. Sun drying is a traditional approach, where nuts are spread on clean surfaces and regularly turned to achieve uniform moisture reduction. Mechanical drying uses controlled airflow and temperature to accelerate the process while maintaining kernel quality. Modern facilities often combine both methods to ensure optimal results.

Moisture Content and Quality Control

Maintaining the correct moisture content is critical for pistachio quality. Typically, pistachios are dried to contain around 5-7% moisture. This range ensures that nuts remain crisp, flavorful, and resistant to microbial contamination.

Quality control during drying involves frequent sampling and monitoring. Moisture meters and visual inspections are used to ensure consistency. Nuts that are over-dried can become brittle, while under-dried nuts may develop mold during storage or shipment. By precisely controlling moisture levels, producers maintain premium quality standards required by international buyers.

Equipment and Technology in Hulling and Drying

Modern hulling and drying operations utilize advanced equipment to optimize efficiency and quality. Hullers, separators, and drying machines are designed to minimize kernel damage while ensuring rapid processing. Automated systems allow for consistent handling of large volumes of nuts, essential for commercial production.

Technology also supports traceability and monitoring. Sensors measure moisture content, temperature, and processing time, ensuring that each batch meets predetermined quality criteria. The integration of technology enhances both productivity and the overall quality of pistachios delivered to markets.

Impact on Export and Marketability

Proper hulling and drying are critical for the exportability of pistachios. Nuts that are improperly processed may fail quality inspections or degrade during transit. Exporters rely on standardized hulling and drying practices to ensure that pistachios reach international buyers in optimal condition.

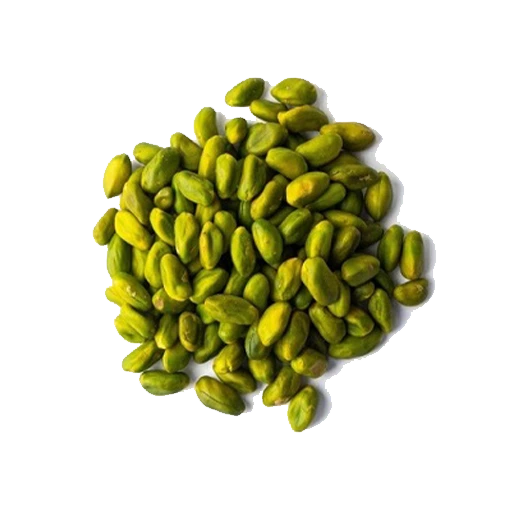

Premium-grade pistachios with intact kernels, uniform size, and proper moisture content are in high demand worldwide. Hulling and drying not only protect these characteristics but also enhance visual appeal, which is a key factor in marketing and pricing.

Common Challenges in Hulling and Drying

Despite technological advances, hulling and drying present several challenges. Timing is critical; delays in hulling can increase the risk of mold, while improper drying can compromise quality. Additionally, variations in kernel size and hull thickness require adjustments in machinery settings to avoid damage.

Environmental conditions, such as humidity and temperature, also affect drying efficiency. Producers must carefully manage these factors to achieve consistent results. Training staff and maintaining equipment are equally important to prevent errors that could reduce nut quality or lead to financial losses.

Best Practices for Hulling and Drying

To achieve optimal results, producers follow several best practices:

Immediate Hulling: Process nuts within 24 hours of harvest to prevent spoilage.

Controlled Drying: Use temperature-regulated mechanical drying combined with occasional sun exposure for even moisture reduction.

Regular Monitoring: Measure moisture content frequently and inspect kernels for damage or mold.

Equipment Maintenance: Ensure hullers and dryers are properly calibrated and maintained.

Quality Segregation: Separate damaged or undersized nuts from premium batches to maintain market standards.

Adhering to these practices ensures that pistachios maintain their flavor, texture, and visual appeal, meeting the expectations of both domestic and international buyers.

Conclusion

Hulling and drying are essential steps in the pistachio production process. Proper hulling removes the perishable outer layer, while precise drying ensures long shelf life, flavor preservation, and resistance to spoilage. Together, these steps directly impact nut quality, marketability, and export potential.

Producers who invest in advanced equipment, technology, and best practices can deliver pistachios that meet international standards and satisfy discerning consumers worldwide. Understanding the importance of these essential steps highlights why premium pistachios are prized for their quality, taste, and reliability in global markets.